Multistage pumps are greatly assistive in industries, particularly where high pressure is required. These pumps are powerful and reliable due to which most companies opt for them for various applications. This blog will discuss how multistage pumps work, what advantages they provide, and where they are utilized.

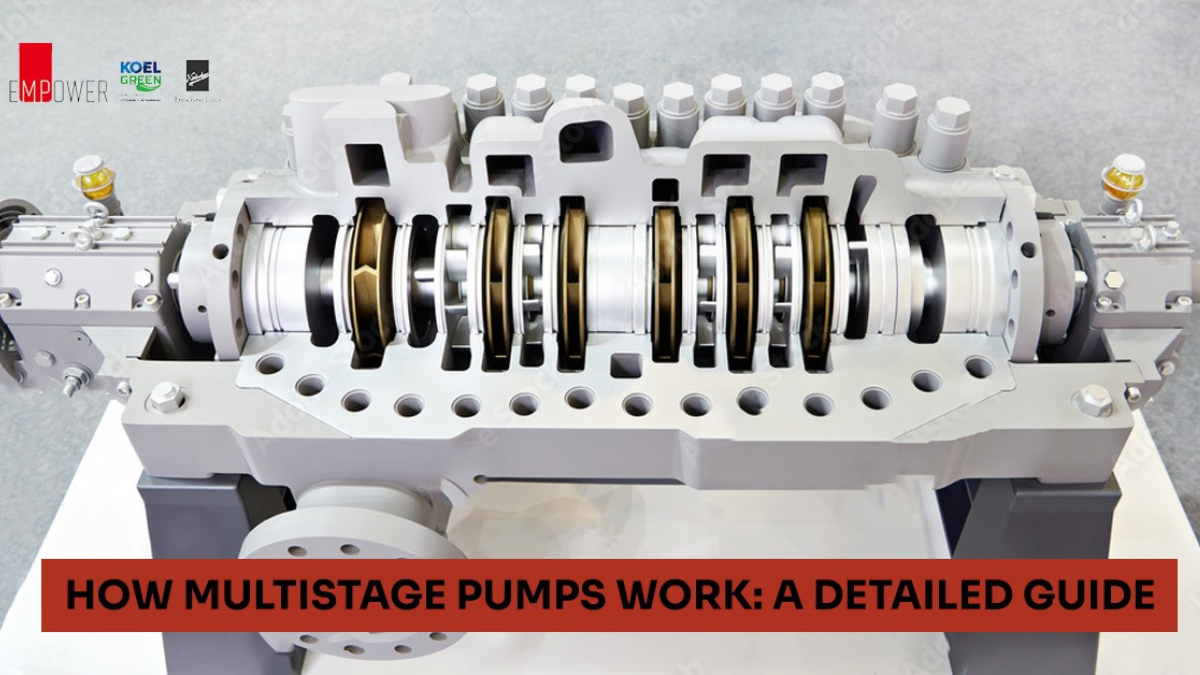

How Does a Multistage Pump Work?

Following is a step-by-step process of how multistage pumps work:

1. Priming the Pump

The pump begins by sucking the fluid into its suction. The fluid enters the first stage at suction pressure.

2. Transporting Fluid Through Impellers

There are some impellers within the pump. The fluid travels from one impeller to another. As it travels, the pressure increases with each stage.

3. Creating the Pressure

Every impeller increases pressure in the fluid. The greater number of impellers in the pump, the greater the pressure. The flow rate, however, remains constant if the pump speed (RPM) remains constant.

Such a design allows multistage pumps to be ideal for applications where a high pressure is required but not a high flow rate.

Advantages of Multistage Pumps

Multistage pumps have a lot of handy features. There are some major benefits listed below:

- High pressure output: Due to many impellers, pumps can support more pressure than single-phase pumps with the same size.

- Compact Size: Although they provide high pressure, multistage pumps are not large in size. They occupy less space in factories or engine rooms.

- Energy Efficient: They use less motor power since the impellers are small and the internal clearances are slender. This is why they are doing more energy than big pumps.

- Low noise: Multistage pumps calm during operation compared to single-phase pumps, especially when intended for high pressure applications.

- Low leakage loss: Low fluids are lost due to leaks as a result of small intervals within the pump, increasing overall efficiency.

Applications of Multistage Pumps

Multistage pumps do not handle dirty liquids or solids, but they handle clean water and other low-viscosity fluids perfectly well. Some of the typical locations where they are utilized are:

1. Boiler Feed

These pumps are used to supply high pressure water in boilers in industries. It is used to produce steam, which is important in many industrial functions.

2. Water Supply Boosting

They are extensively utilized in municipal city water supplies. They are utilized for managing and boosting water pressure from treatment plants to consumers and businesses.

3. Irrigation

Farmers utilize such pumps to irrigate vast fields. They facilitate water delivery over a long distance and foster proper crop development

4. Water Circulation

They find applications in systems requiring constant water flow, such as swimming pools, water treatment facilities, and cooling systems.

5. Fire Fighting

In fire-fighting arrangements, multistage pumps provide solid and consistent water flow, which is essential in effectively suppressing fires promptly.

Picking the Right Multistage Pump

Selecting an appropriate multistage pump matters for hassle-free operation. Here’s what you need to consider:

Flow Rate

Know how much fluid requires movement. This assists you in selecting a pump that matches the requirement.

Pressure Requirements

Determine the pressure needed within your system. This assists in choosing the proper number of stages or impellers for the pump.

Type of Fluid

Not all pumps can be designed for all fluids. Make sure the pump is compatible with the liquid with which you will be working, especially in temperature and viscosity.

Energy Source

Multistage pumps can either be powered using electricity or diesel. If you are in an area where electricity is not reliable, then diesel engine pump sets work just as well.

You may also check for kirloskar pump set dealers, as they sell a range of reliable diesel engine pump sets that are known to be dependable in most industrial and agricultural processes.

Conclusion

Multistage pumps are an intelligent option for high-pressure fluid transfer in industries. Boiler feed to fire fighting systems, these pumps provide uniform performance. Be it an electric or diesel engine pump set, selecting the best one guarantees improved efficiency and durability.

For quality and durable solutions, purchase from kirloskar pump set dealers, famous for their quality and variety of multistage pumps and diesel pump sets.

Leave a Reply